|

Andrew F. Braham

Laboratory Capabilities

Click on a category below to jump down

Material Production |

Asphalt Binder Testing |

Asphalt Emulsion Testing |

Asphalt Mixture Testing |

Asphalt Emulsion Treatment Testing |

TREAT Mobile Lab

This webpage briefly describes the laboratory capabilities of flexible pavement materials in the Civil Engineering department at the University of Arkansas. Pavement material research includes the areas of asphalt materials, asphalt emulsion, asphalt foam, pavement maintenance, and pavement rehabilitation. Laboratory capabilities include material production, asphalt binder testing, asphalt emulsion testing, and asphalt mixture testing. In addition, the TREAT Mobile Lab has three primary asphalt emulsion capabilities.

All of this work could not be done without my graduate and undergraduate research assistants. Figure 1 shows a picture of the research group at Arkansas Department of Transportation’s 2023 TRC Conference.

Figure 1: Research Group at 2023 TRC Conference

Material Production

There are several methods of producing flexible pavement samples in the lab at the University of Arkansas. For asphalt materials, these methods include gyratory compactors, an asphalt foaming device, asphalt emulsion manufacturing devices, and a rock crusher. The equipment available is described in more detail below.

Gyratory compactors

The lab has two gyratory compactors, a Troxler Model 5850 and a Pine Instrument Company AFG2AS. The Troxler 5850 is capable of compacting samples containing water, with specially designed perforated molds and a catch-basin below the molds to capture any water forced out of the sample during compaction. This is especially important when compacting Cold In-place Recycling or Full-Depth Reclamation samples. The Pine AFG2AS is the latest compactor model from Pine and includes shear measurement instrumentation. The amount of shear energy expended during compaction is becoming an important parameter to capture while evaluating all types of pavement materials that require compaction in the field. Figure 2 below shows the Troxler 5850 and Pine AFG2AS. All gyratory compactors conform to AASHTO T 312/ASTM D6925.

Figure 2: Troxler Model 5850 (top) and Pine Instrument Company AFG2AS (bottom)

Asphalt foam

Asphalt foam has two applications in pavement materials. First, it can be used for in place pavement rehabilitation, including Cold In-place Recycling (CIR) and Full-Depth Reclamation (FDR). Second, it is a type of method to produce Warm Mix Asphalt (WMA). The lab has a Wirtgen WLB 10S foaming machine. The Wirtgen machine was specifically designed for FDR foaming design, but has also been used in industry and academia to produce CIR and WMA mixtures. The Wirtgen also comes with a dual-shaft pugmill mixer capable of mixing up to 66 lb (30 kg) of material (WLM 30). This mixer is useful for making large batch samples that would not be possible to produce in the standard five gallon (19 liter) paddle mixer. These two machines are shown in Figure 3.

Figure 3: Top - Wirtgen WLM 30 mixer & WLB 10S foaming machine and bottom - Wirtgen WLM 30 mixer without material (left) and with material (right)

Asphalt emulsion

The laboratory has four lab-scale asphalt emulsion manufacturing devices: two in-line asphalt emulsion mills, one recirculating emulsion mill, and a high speed shear mixer. With these mills, we are able to produce our own asphalt emulsions and allows research into emulsifier chemistries, asphalt binder types, asphalt binder modification, influence of material temperature, pH, and other factors of asphalt emulsion formulation development.

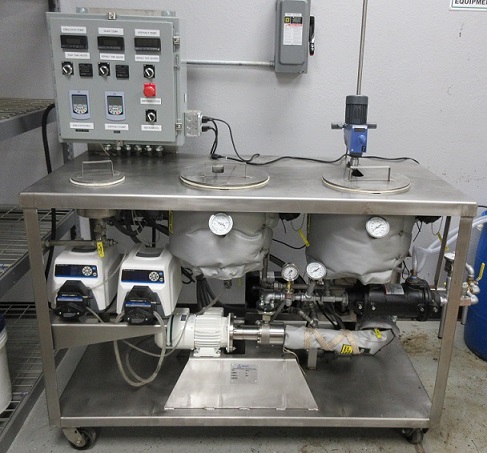

One of the in-line asphalt emulsion mills is a VSS EmulTech Laboratory Emulsion Plant. It features a colloid mill with variable milling speed. The optimal asphalt emulsion batch size for this mill is 2-10 gallons. Figure 4 shows a picture of the VSS mill in the lab.

Figure 4: The VSS EmulTech Laboratory Emulsion Plant

The second in-line asphalt emulsion mill is a Bergkamp Laboratory Scale Emulsion Mill. It features a colloid mill with variable milling speed. The optimal asphalt emulsion batch size for this mill is 3 gallons. Figure 5 shows a picture of the Bergkamp mill.

Figure 5: The Bergkamp Laboratory Scale Emulsion Mill

The recirculating emulsion mill is a laboratory bench-top scale Herbert Rink asphalt emulsion mill. It features a colloid mill with a fixed milling speed. The optimal asphalt emulsion batch size for this mill is 0.25-0.50 gallons. Figure 6 shows a picture of the Herbert Rink mill.

Figure 6: Herbert Rink asphalt emulsion mill

The high speed shear mixer mill is a Silverson AX5 Heavy Duty Lab Mixer, with a standard emulsion screen and head (EMSC, and STEH). It features an axial mixing head with a variable mixing speed. The optimal asphalt emulsion batch size for this mill is 1-2 gallons. Figure 7 shows a picture of the Silverson AX5 mixer.

Figure 7: Silverson AX5 Heavy Duty Lab Mixer

Laboratory crusher

Often, it is necessary to crush pavement cores from the field in order to break them down for future use. Especially when looking at Cold In-place Recycling or Full Depth Reclamation, it is critical to be able to control the gradation of crushed material. Therefore, the laboratory purchased a RHINO Jaw Crusher in order to further process material. Figure 8 shows the crushing unit.

Figure 8: RHINO Jaw Crusher

Click here to return to top

Asphalt Binder Testing

Several tests are available in order to measure properties of asphalt binder. The equipment includes a Brookfield Rotational Viscometer, a Dynamic Shear Rheometer, Bending Beam Rheometer Plus, and a Rolling Thin Film Oven.

Brookfield Rotational Viscometer

The lab has a Brookfield DV-II+ Pro Viscometer that meets standards AASHTO T 316 and ASTM D4402. The viscometer measures the workability of asphalt binder, which is critical for production and construction. With four SC spindles (SC4-21, SC4-27, SC4-28, SC4-29) a full range of products can be tested. In addition, the unit was purchased with a Helipath stand. This allows the viscometer to raise and lower during testing, creating a helical path and eliminating channeling of non-flowing substances. As new products are developed and evaluated for pavement materials, flexibility with testing equipment is critical. Figure 9 shows the viscometer with the thermosel and Helipath stand.

Figure 9: Brookfield Rotational Viscometer

Dynamic Hybrid Rheometer

For understanding the performance of asphalt binder at high temperatures and intermediate temperatures, a Dynamic Shear Rheometer (DSR) is necessary. For capturing both rutting and fatigue cracking, AASHTO T 315/ASTM D7175 is used to measure G* and sin d. A newer test, Multiple Stress Creep Recovery (MSCR), has shown to do a better job of predicting rutting for polymer modified asphalt binders. AASHTO TP 70/ASTM D7405 is the procedure for measuring Jnr, the primary measurement from the MSCR test. For more details on fatigue damage of asphalt binders, the DSR can measure Linear Amplitude Sweep (LAS), following AASHTO T 391. Finally, for yielding and elastic recovery behavior at intermediate temperatures, the Binder Yield Energy Test (BYET) is available, following AASHTO TP 123. The lab has a TA Instruments HR-2 Discovery Hybrid Rheometer (DHR) to capture G*, sin d, Jnr, LAS, and BYET. To control testing temperatures, the DHR is equipped with a Peltier plate and environmental test chamber. Figure 10 shows the DHR.

Figure 10: TA Instruments HR-2 Discovery Hybrid Rheometer

Bending Beam Rheometer Plus

For understanding the performance of asphalt binder at low temperatures, a Bending Beam Rheometer (BBR) is necessary. The BBR is able to capture both the stiffness (S) and relaxation (m-value) of asphalt binders following AASHTO T 313/ASTM D6648. These parameters can be correlated to low-temperature cracking susceptibility of asphalt binder. The lab has a PaveTest Bending Beam Rheometer Plus. Figure 11 shows the BBR Plus.

Figure 11: PaveTest Bending Beam Rheometer Plus

Rolling Thin Film Oven

The lab has a Rolling Thin Film Oven in order to short-term age the asphalt cement according to AASHTO T 240/ASTM D2872. This aging is representative of the aging that occurs during the high temperatures of production and construction. After aging, rutting and cracking characteristics can be measured. Figure 12 shows the lab’s RTFO.

Figure 12: Rolling Thin Film Oven

Click here to return to top

Asphalt Emulsion Testing

While the majority of tests for asphalt emulsions are over 50 years old (see AASHTO T 59), there are several innovative tests that can be run at the University of Arkansas in order to quantify properties of asphalt emulsion. While the lab is able to run distillation, evaporation, penetration, and other tests in AASHTO M 140, M 208, and M 316, this summary will focus on particle size, paddle viscosity, and modified storage stability.

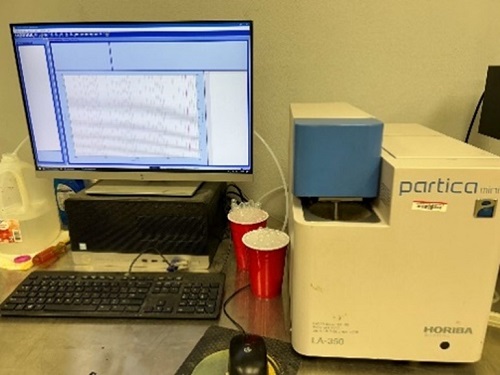

The lab has a Horiba LA-350 AP laser diffraction particle size analyzer. Particle size of asphalt emulsion ranges from approximately 0.1-20 microns. In general, larger particle size decreases viscosity and smaller, narrower particle size increases performance. There is no current standard to measure particle size of asphalt emulsion. Figure 13 shows the particle size analyzer.

Figure 13: Horiba LA-350 AP laser diffraction particle size analyzer

The lab has a Cannon Digital Paddle Viscometer. Since asphalt emulsion is not a homogeneous material, the standard cup/spindle test used for asphalt binder is not appropriate. The paddle viscometer follows ASTM D7726. Figure 14 shows the paddle viscometer.

Figure 14: Cannon Digital Paddle Viscometer

Finally, while the lab is able to run storage stability of asphalt emulsion following AASHTO T 59, this test requires 500 mL of asphalt emulsion (approximately 500 g) to run a single test. In a laboratory setting, this is a large amount of emulsion. Therefore, the lab is developing a small-scale stability test that uses only 125 g of asphalt emulsion (approximately 125 mL) in an Erlenmeyer flask. This configuration is shown in Figure 15.

Figure 15: Small scale storage stability test of asphalt emulsion

Click here to return to top

Asphalt Mixture Testing

The University of Arkansas has a very comprehensive asphalt mixture testing lab. Equipment is available for the conventional asphalt concrete tests, including bulk specific gravity (AASHTO T 166/ASTM D2726), maximum specific gravity (AASHTO T 209/ASTM D2041), Marshal Stability (AASHTO T 245/ASTM D6927) and tensile strength ratio (AASHTO T 283/ASTM D4867). In addition, the lab has the capability to capture moisture damage, rutting, cracking, dynamic modulus, flow, fatigue, shear modulus, and small-scale bending beam fatigue. The equipment available is described in more detail below.

Moisture Damage: Hamburg Wheel Tracking Test

As mentioned, the laboratory has the capability to run tensile strength ratio, which is a moisture damage test, but it also has an InstroTek Hamburg Wheel Tracking Test, or HWTT (AASHTO T 324). The HWTT is a moisture torture test, where submerged samples of compacted asphalt mixtures have a steel wheel rolled over the top of the sample. Figure 16 shows the HWTT equipment.

Figure 16: InstroTek Hamburg Wheel Tracking Test

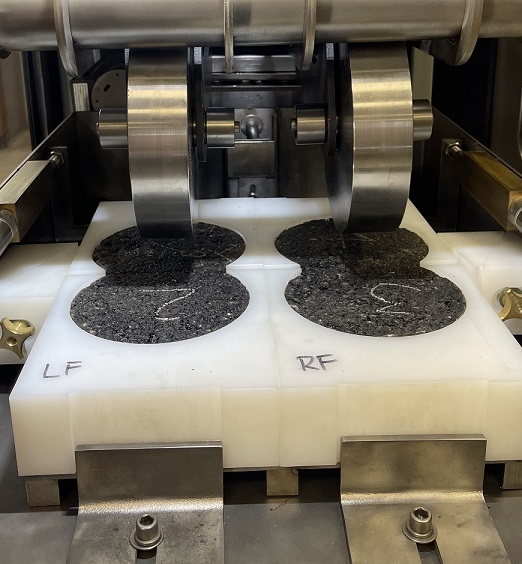

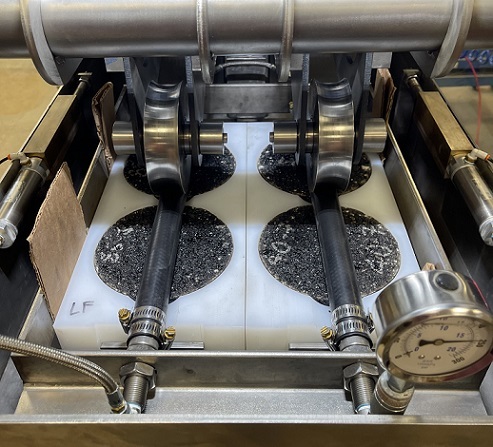

Rutting: Asphalt Pavement Analyzer

The lab has one piece of equipment that is exclusively designed to capture rutting, the Asphalt Pavement Analyzer, or APA (ARDOT 480). Our equipment is the “junior” model (Jr.) and is manufactured by Pavement Technology, Inc. Note that the APA is used to evaluate rutting in Arkansas Department of Transportation’s (ARDOT’s) balanced mix design procedure. Figure 17 shows the APA Jr. equipment.

Figure 17: Pavement Technology Asphalt Pavement Analyzer Jr.

Cracking: IDEAL-CT

The lab has two small load frames that are able to capture three cracking tests at ambient temperatures. First, we are able to run the LSU SCB (ASTM D8044), which captures the critical strain energy release rate. Second, we can run the Illinois Flexibility Index Test (AASTHO T 393), which captures the fracture energy, post peak slope, and flexibility index. Third, we are able to run the Indirect Tensile Cracking Test, or IDEAL-CT (ASTM D8225), which captures the CTIndex. Note that the IDEAL-CT is used to evaluate cracking in ARDOT’s balanced mix design procedure. Figure 18 shows the IDEAL-CT equipment, which is a Humbolt load frame.

Figure 18: The IDEAL-CT equipment using a Humbolt load frame

AsphaltQube

The AsphaltQube, which is manufactured by Controls Group, has the capability to run many tests: dynamic modulus, flow number, and flow time (AASHTO T 378); unconfined uniaxial fatigue (more commonly known as S-VECD, AASHTO TP 107); and I-FIT and LSU SCB. Unfortunately, the S-VECD test has never functioned correclty on our equipment. In addition, it can run from -10C to +60C. Figure 19 shows a picture of the AsphaltQube.

Figure 19: Controls Group AsphaltQube

Dynamic Hybrid Rheometer

A significant drawback to testing asphalt mixtures is the large amount of material required for testing. In order to attempt to reduce the amount of material, the Dynamic Hybrid Rheometer has been adapted by many researchers to run a torsion bar test, which captures shear modulus. These relatively small samples, only 0.5x0.5x2 inches (12x12x50 mm), are run in the lab’s Dynamic Hybrid Rheometer. With special fixtures, the torsion bar is able to quantify the rutting susceptibility of asphalt mixtures. The HR-2 is equipment with an environmental test chamber that, with liquid nitrogen, is able to span the entire service temperature of asphalt concrete, from -50°C to +60°C and even higher if desired. Figure 20 shows a picture of a torsion bar sample and the environmental test chamber.

Figure 20: Torsion bar sample (top) and environmental test chamber on the DHR (bottom)

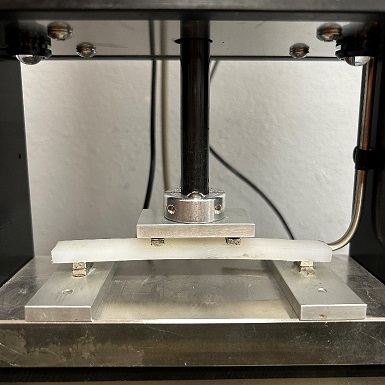

Bending Beam Rheometer Plus

As mentioned above, the lab has a PaveTest Bending Beam Rheometer Plus (BBR Plus). This machine can not only run the classic BBR test (creep loading) on asphalt binder samples, but also on asphalt mixture samples (AASHTO TP 125). In addition, the BBR Plus is able to run dynamic, four-point bending fatigue tests on asphalt mixture samples. There is no current standard to measure fatigue properties of BBR sized asphalt mixture samples. Figure 21 shows a picture of a plastic calibration sample in the fatigue loading frame.

Figure 21: Dynamic loading of asphalt mixtures using a PaveTest BBR Plus

Click here to return to top

Asphalt Emulsion Treatment Testing

With the emulsion lab mill, it is important to be able to run tests of asphalt emulsion treatments. Almost all of the tests described in the asphalt mixture section can be run on both Cold In-place Recycling (CIR), cold mix asphalt, and Full-Depth Reclamation (FDR) mixtures. In addition, the raveling test (ASTM D7196) can be run on these three pavement materials. Figure 22 shows the Hobart Mixer along with the raveling fixtures to run the raveling test.

In addition to the raveling test, the Hobart Mixer is able to run the sweep test (ASTM D7000) for chip seals and the wet track abrasion test (ASTM D3910/ISSA TB100) for slurry seals and micro surfacing. This is done by simply removing the raveling fixtures and replacing it with the appropriate fixtures for either the sweep test or the wet track abrasion test.

Figure 22: Hobart HL120 Mixer

Click here to return to top

TREAT Mobile Lab

Mission and Vision

The mission of TREAT is to enhance knowledge of asphalt emulsion and asphalt emulsion based treatments to agency employees, consultants, contractors, students, and others who are interested in learning more about extending their pavement life while reducing costs. This is achieved by providing foundational knowledge in a classroom setting and then moving to the field for live demonstrations. The objectives of TREAT are:

o Define pavement preservation and asphalt emulsions

o Describe the uses of asphalt emulsion in maintenance and rehabilitation treatments

o Identify the sequence of constructing high-quality chip seals and slurry surfacing

o List key concepts of specifying and inspecting asphalt emulsion maintenance treatments

o Quantify the economic, environmental, and safety benefits of pavement preservation

The vision of TREAT is that road owners will treat roads that are in good condition, by applying pavement preservation to their roadway network. By taking care of roads in good condition, the cost of maintaining a road over time will decrease and the life of the road will increase.

The TREAT Mobile lab consists of trailers and two mini-applicators, which will be described in more detail below.

TREAT Trailers

The TREAT Mobile lab consists of two trailers. Both trailers can be run off shore power, and both have generators available if shore power is not an option.

The first trailer is a 32x8.5 foot gooseneck trailer, and is the laboratory trailer. It contains the Bergkamp in-line laboratory scale emulsion mill, two small Despatch ovens, a sink, a station to manufacture soap solution for asphalt emulsions, and plenty of counter and storage space. Figure 23 shows two interior pictures and one exterior picture of the laboratory trailer.

Figure 23: The interior of the TREAT laboratory trailer (top) and the exterior (bottom)

The second trailer is a 16x7 foot bumper trailer, and is the storage trailer. It contains two large Despatch ovens, additional counter and storage space, and houses the two mini-applicators. Figure 24 shows an interior and exterior picture of the storage trailer.

Figure 24: The interior of the TREAT storage trailer (top) and the exterior (bottom)

TREAT Mini-Applicators

In addition to the two trailers, the TREAT Mobile Lab has two mini-applicators, one for an asphalt emulsion based spray application and the second for an asphalt emulsion mix application.

The spray mini-applicator has a 3 gallon tank and a 4 foot wide spray bar. Emulsion can be sprayed at three different application rates: 0.35, 0.42, 0.50 gallons per square yard, and covers approximately 3x7 feet. This will allow for appropriate application rates depending on the existing surface of the roadway. This applicator can place the asphalt emulsion for fog seals, rejuvenating fog seals, or chip seals. Figure 25 shows a picture of the spray applicator.

Figure 25: The TREAT mini spray applicator

The mix mini-applicator has a small slurry box that is pulled by the powertrain. Emulsion and aggregate are mixed in a bucket-mixer and poured into the slurry box as it is being pulled. The resulting section is approximately 2x6 feet. This applicator can place either slurry seal or micro surfacing. Figure 26 shows a picture of the mix applicator.

Figure 26: The TREAT mini mix applicator

Click here to return to top

Last updated: July 2025

|